Glenn Randall

I-Search Rough

Draft

Week # 13

Fluorocarbon

Ski Waxes

When I started skiing as a small

child, I could never have imagined what skiing would do to me. The first time I skied, I was probably no older

than two and my parents had merely put skis on my feet and let me wander around

the house with them on. I'm not sure

when exactly I got on snow, but I know that ever since then I've been hooked.

Even

as a small child, I had a huge urge to race.

My parents told me that I could race as soon as I could climb the

biggest hill on the local 1 km course.

While I now know that the hill was very small and gradual, at the time

it was a momentous trek, seeming more like cycling's L’Alpe D'Huez than the

small hill that it actually is.

Ever

since I could climb the hill and have been allowed to race, I have loved

it. As I got better and learned about

topics such as force, energy, and friction, I began to wonder why a ski works,

and what sort of magic makes some waxes faster than others. Since I have been a small child, I have grown

up around skis and ski waxes, but I never knew why or how they worked. The purpose of this paper is to find out what

makes skis fast, how fluorocarbon waxes differ from other types of wax, and

what makes fluorocarbons fast.

There

are two types of ski waxes, glide and kick.

Kick wax is used in classic skiing, but not in skate skiing. It is applied to the ski to keep the ski from

sliding backwards, giving the ski what skiers call "kick." This term merely describes how well the ski

holds to the snow when the skier kicks backwards on the snow for foreword

propulsion. It is relatively easy to

imagine how a stickier kick wax works better for icy snow, and a less sticky

kick wax works better for slower snow.

Glide

wax is what makes the ski fast. It is

more complicated. Most glide waxes have

to be melted into the base of the ski.

Ski bases have been made of polyethylene for quite some time (Talbot

8). Polyethylene skis are translucent (Onion). Eventually, people figured out that graphite

could be added to ski bases (Charonnat, Understanding Glide Waxes). Graphite is a soft black form of carbon

(Advanced Dictionary). It reduces static

electricity and transfers heat to the center of the ski, speeding it up

(Charonnat, Understanding Glide Waxes).

Modern ski bases have a microscopic structure made up of many hair-like

structures. This creates places where

ski wax can be absorbed (Talbot 8).

Most

people think of snow and ice as being characteristically slick. It is not.

In fact, at cold enough temperatures, people can walk on ice without

fear of slipping. This is because under

the pressure of a foot or a ski a thin layer snow and ice tends to melt. A 100 lb skier going 60 mph down a hill

produces energy equivalent to if they had three 100 W light bulbs on the bottom

of their ski (McKibben). This thin layer

lubricates the area between the ice and the foot (Onion). When trying to get to a car on a snowy day,

this may be bad, but when trying to ski fast on snow, this is a very good

thing.

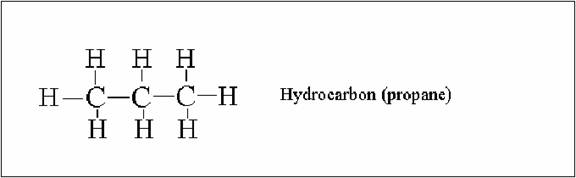

Cheap

glide waxes that can be bought in the store are usually hydrocarbons

(Charonnat, Fluorinated Waxes). A

hydrocarbon is a chain of carbon atoms with hydrogen atoms bonded to the carbon

atoms (Charonnat, Fluorinated Waxes).

Two hydrogen atoms are bonded to every carbon atom throughout most of

the hydrocarbon molecule. Hydrocarbons

exist in many forms. Polyethylene, the

ski base material, is a very long hydrocarbon, consisting of thousands of

carbon atoms. This length gives it a

very high melting point and an even higher boiling point. On the other extreme, propane is a

hydrocarbon consisting of three carbon atoms (Talbot 8).

Figure

1: Talbot, Chris. “The Science of Ski Waxes.” (

Before

the use of hydrocarbons, ski racers made their own wax, with conglomerations of

bear fat, honey, sap, and oil, to name a few ingredients. The recipes of waxes were top secret, but

crude (Talbot 3). Today, wax companies

have top-secret recipes of chemicals.

They are sold to whomever wants to buy them (Toko® Tech Manual).

There

are three types of hydrocarbons used in glide wax. Paraffins are chains of 25-35 carbon

atoms. They are soft candle-like waxes

used for warm temperatures. Paraffins

have a low coefficient of friction, meaning that they do not experience much

friction. Because they are such short

chains, snow crystals easily puncture paraffins. This makes them not work well in colder

conditions, when snow crystals are very hard and pointy (Charonnat, Fluorinated

Waxes).

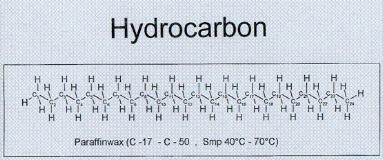

The

diagram below shows a hydrocarbon. The

C's are carbon atoms and the H's are hydrogen atoms. The subscripted numbers next to the carbon

atoms show which carbon atom it is, numbering from left to right. This paraffin has 24 carbon atoms.

Figure

2: "TokoÒ Chemical Makeup of Glide

Wax" Toko® Information Center

Branched

hydrocarbons with 25-50 carbon atoms are known as microcrystalline. Microcrystalline waxes have a slightly higher

coefficient of friction than paraffins.

This means that they experience more friction than paraffins. Microcrystalline, however, has more strength

than paraffins, so it can be used in colder snow, when snow and ice crystals

are long and sharp. Microcrystalline and

paraffins are often used together in the same wax, because hydrocarbons bond

together fairly well (Charonnat, Fluorinated Waxes).

A

third type of hydrocarbon is synthetic wax.

Synthetic waxes are slightly branched and contain 50-60 carbon

atoms. Because they are so big, they

have a high melting point and are also very hard at skiing temperatures. This makes them work very well on cold snow

(Talbot 10).

Fluorocarbon

waxes are very similar to hydrocarbons, except that fluorine atoms have

replaced some or all of the hydrogen atoms.

Fluorine is the most electronegative element known. This means that fluorine attracts negatively

charged electrons better than element.

This makes fluorine very hydrophobic, which means that it repels

water. Wax companies borrowed the idea

of using fluorocarbons to repel water from fishermen. Fluorocarbons would be painted on the bottoms

of boats to help repel water (Charonnat, Fluorinated Waxes).

The

first fluorocarbon wax was polytetrafluoroethylene, or PTFE. PTFE is also known as Teflonä. PTFE is a branched fluorocarbon chain with

over 500 carbon atoms (Charonnat, Fluorinated Waxes).

The

first commercially available fluorocarbon ski wax was Cera F, produced by

Swix. Cera F is a perfluorocarbon,

meaning that fluorine atoms have replaced all of the hydrogen atoms. Perfluorocarbons usually have around 20

carbon atoms, making their melting points low (Charonnat, Fluorinated Waxes).

At

the 1987 Oberstdorf World Championships, the Italians started using

fluorocarbons. By the 1988 Calgary

Olympics, fluorocarbons were being used extensively (Karlson).

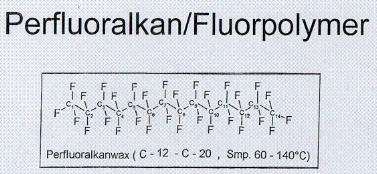

Figure

3, shown below, shows a perfluorocarbon.

The spelling in figure 3 is due to the fact that it was originally made

for Europeans. As with the figure 2,

each C corresponds to a carbon atom, with the subscripts next to the carbons

showing which carbon is there, numbering from left to right. Each F represents a fluorine atom. Because this is a perfluorocarbon, a fluorine

atom has replaced every hydrogen atom.

This fluorocarbon has 14 carbon atoms.

Figure

3: “Toko® Chemical Makeup of Glide

Wax.” Toko® Information Center

Fluorocarbons

have a very negative surface, because of fluorine's high

electronegativity. Fluorocarbon waxes

not only repel water, but also dirt particles, which tend to be negatively

charged. This keeps dirt off of ski

bases. Dirt slows down skis, so this is

important to skiers. This makes

fluorocarbons work very well during spring skiing, when snow tends to be very

dirty (Charonnat, Fluorinated Waxes).

Fluorocarbons

are very expensive, mainly because they are produced at very few places in the

world. Wax companies buy fluorocarbons from

these facilities and then customize them.

Fluorocarbons also lack structural strength, like paraffins (Charonnat,

Fluorinated Waxes). Most fluorocarbons

also have a high melting point. This

means waxing irons must be very hot in order to melt fluorocarbons into skis

(Glenn Randall).

Torbjorn

Karlson, a former US Ski Team coach and a co-founder of fasterskier.com, wrote

of waxing with fluorocarbons in an e-mail interview, "You use high

heat, have to be careful and constantly move the iron - you have to

develop a feel for how to do

this right."

Chlorofluorocarbons, or CFCs, are banned

refrigerants. CFCs contain chlorine,

which makes them damaging to the ozone layer.

Fluorocarbons and chlorofluorocarbons are not the same. Fluorocarbons do not contain chlorine, which

is what makes CFCs damaging to the atmosphere (Charonnat, Understanding Glide

Waxes).

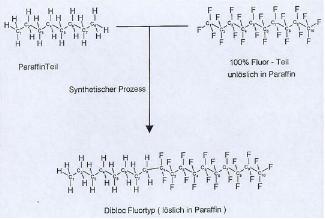

Fluorocarbons and hydrocarbons do not typically

mix well together. This can be compared

to oil and water. The reason is that

hydrocarbons have electrically neutral surfaces, while fluorocarbons have

negatively charged surfaces. Ski bases,

as I have written before, are made with hydrocarbons. In order to mix fluorocarbons and hydrocarbons,

a hybrid is made (Talbot 11).

Fluorinated waxes have one side that is

fluorocarbon, and the other side that is hydrocarbon (Charonnat, Fluorinated

Waxes). Fluorinated waxes are made with

different amounts of fluorine. More

fluorocarbon is not always better. Waxes

for dry, cold conditions fluorinated waxes usually contain much less fluorine

than waxes for warm, wet conditions.

This is because not as much snow melts at the colder conditions, and

substances with more strength than fluorocarbons are needed (Toko® Tech Manual

4).

Figure 4, on the next page, shows how fluorinated

waxes actually consist of a fluorocarbon molecule that is combined with a

paraffin molecule. This figure is also

made for Europeans, so spellings for many words are different, but this figure

illustrates what fluorinated waxes are quite well.

Figure

4: “Toko® Chemical Makeup of Glide

Wax.” Toko® Information Center

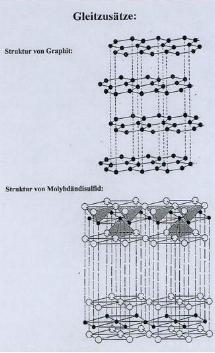

Other

types of waxes include graphite waxes and molybdenum waxes. These waxes are mainly used to decrease

static charges and lubricate the ski bottom (Toko® Tech Manual 4). An example of the atomic structures of

graphite and molybdenum waxes are shown in figure 5, below. Graphite is shown on the top, molybdenum

shown on the bottom.

Figure

5: “Toko® Chemical Makeup of Glide

Wax.” Toko® Information Center

Every

skier wants fast skis, whether they are backcountry skiers or Olympic

champions. For backcountry and

recreational skiers, fast skis just make skiing easier, but most of these

skiers do not do too much to make their skis fast. I often see skiers drive down the road with

skis mounted on the top of their vehicle.

This fills the skis with dirt and makes them slower. When these skiers get to the ski trails, many

of them put on their skis and ski through the parking lot. This scratches the bottom of the ski and

fills the base with dirt, both making the ski slower.

Most

of these recreational skiers do not know better than skiing through a parking

lot. Many of them also don't find fast

skis important enough to spend the money to buy wax and then spend the time to

put it on. Some do, but many of these

skiers take their skis to ski shops for a "tuning."

Ski

racers, on the other hand, are willing to do what it takes to have fast

skis. Greg Randall, my coach, told me in

an interview, "There are some races that without fluorocarbons, you would

lose a minute in a 5 km." In a 5 km

race, seconds and tenths of seconds usually are the difference between

skiers. For racers, the threat of losing

a minute or the draw of gaining a minute is well worth expensive fluorocarbon

waxes, or even sending skis to be stone ground by experts with expensive

machines around the country.

Torbjorn

Karlson, in the e-mail interview, stated, "The

best feel is when you out glide your

competition." This draw of having

faster skis than the other racers encourages most skiers to spend many hours

waxing with hydrocarbon training waxes, and then spend more time waxing on

fluorocarbons.

I

have found that having fast skis is very important. Races can be won or lost by the speed of the

skis. While it is the skier on the ski that

is the most important, to win a big race, a skier needs fast skis. While watching the 2003 World Championship

Nordic Combined from Val de Fiem on television, I could tell that Johnny

Spilane, the winner of the race, had much faster skis than anybody around him.

I

have waxed skis a lot. I never knew

quite what I was doing, just that I was making the skis fast. Now I actually know what is happening while I

wax, and what will happen when the ski is on the snow. Skiing fast, for me, has been well worth

every moment spent waxing skis.

My

parents have never let me wax with fluorocarbon waxes. This is because they give off hazardous fumes

when ironed into the ski. Fluorocarbon

waxes can reduce lung function 10-25%.

According to Greg Randall, the effects of waxing with fluorocarbons

without a respirator are, “Sore throat, hacking up white stuff the next day,

and an angry wife.” I have asthma, so

not only would I get the regular ill effects of fluorocarbon fumes, but also

probably have problems with my asthma.

Respirators keep others from having ill effects, but that is a risk that

my parents are not willing to take, especially since we only wax with

fluorocarbons for races, so any ill effects would be during a race the day

after waxing with fluorocarbons.

Greg

Randall uses a respirator when he waxes with fluorocarbons. With a respirator, he feels no ill

effects. Torbjorn Karlson, on the other

hand, says, I used to use one when I daily waxed skis for other skiers. I often

find myself not using one these days since I mostly only wax my own skis and

are not feeling any ill effects. I might go back to using one since it's not

uncomfortable wearing one for that short of a period. It's better to be safe

than sorry later.”

I

have also heard others talk about waxing.

The US Ski Team had people hospitalized last year after they “overdosed”

on fluorocarbons. Now, the US Ski Team

always uses respirators that look more like gas masks. They supposedly have a battery, and I know

that these respirators cover the entire face.

This is much more than the simple respirators my family uses.

Greg

says of waxing with fluorocarbons, “It’s just smoky, and I have stuff all over

my glasses, especially if the iron’s too hot.”

In

my experience with other hydrocarbons, I never have smoke and debris floating

around. I only see wax melt into the

ski, and then solidify.

I

have raced on very fast skis before.

Fast skis make skiing seem effortless.

With fast skis, I have total control of the ski and move very quickly on

uphills, flats, and downhills. Fast skis

also have a special mental advantage.

When I do have fast skis, I know that my skis are going to be as fast if

not faster than anybody’s on the course.

This gives me a confidence boost and makes me more excited for the race.

Slow

skis, on the other hand, are terrible. I

have skied on very slow skis before. I

usually don’t have slow skis other than in training, and then only if I am

about to have a race with entirely different conditions than I am skiing

on. Slow skis break morale and require a

lot of effort.

Everyone

agrees, fluorocarbons are fast. If they

weren’t fast, people wouldn’t be willing to buy them and wax with them. Torbjorn says he waxes with fluorocarbons at

“80-90% of all races.” Greg waxes with

fluorocarbons, “weekly during ski season.”

While

fluorocarbons may be expensive and unpleasant to wax with, they are fast and

give a good control of skis. Most skiers

feel that these benefits outweigh the drawbacks of waxing with fluorocarbons. Waxing with fluorocarbons is just one of the

sacrifices skiers make, just like hard training or long trips to races or snow.

I

predict that in the near future, skis may be become electrical. The electricity would melt a thin layer of

water from the ice on the bottom of the ski.

This would increase the need for fluorocarbons, because there would

never be conditions cold enough to have snow not melt. Synthetic waxes would suddenly become almost

obsolete, because they are for cold conditions, when the snow underneath the ski

does not melt.

Through

the course of writing this paper, I have learned that fluorocarbons work for

real reasons. They do not work with some

sort of magic. Most skiers don’t know

much about how fluorocarbons work, only that they do. I now understand how fluorocarbons work on an

atomic level, microscopic level, and macroscopic level.

I

feel that knowing more about how skis glide and waxes work gives a better

understanding of the entire sport.

Skiing is more than just a recreational activity. It is also a way of life, meeting people, and

thinking. Understanding how a ski

actually glides along the snow gives a greater appreciation of skiing, skiers,

and nature.

Works Cited

Charonnat,

Noel. “Fluorinated Waxes.” Sierra Nordic (

Charonnat,

Noel. “Understanding Glide Waxes.” Sierra Nordic (

“Graphite.” Advanced Dictionary. 1988 ed.

Karlsen,

Torbjorn. E-mail interview.

McKibben,

Bill. “Frozen World.” Cross-Country Skier February, 2004 23.4 http://www.crosscountryskier.com/frozen_world_feb_2004.html.

Onion,

Amanda. “Skiing Science: How the Right Wax Can Make All the

Difference.” ABC News (

Randall, Glenn. Personal experience.

Many cities in many states at many times.

Randall,

Greg. Personal Interview.

Talbot,

Chris. “The Science of Ski Waxes.” (

“Toko®

Chemical Makeup of Glide Wax.” Toko®

Information Center

“Toko® Tech Manual Nordic 2003/2004.” Toko® Information Center 17 pp,